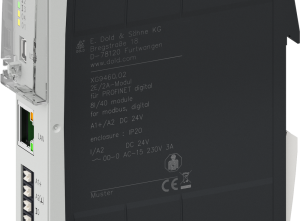

Full functionality at the front

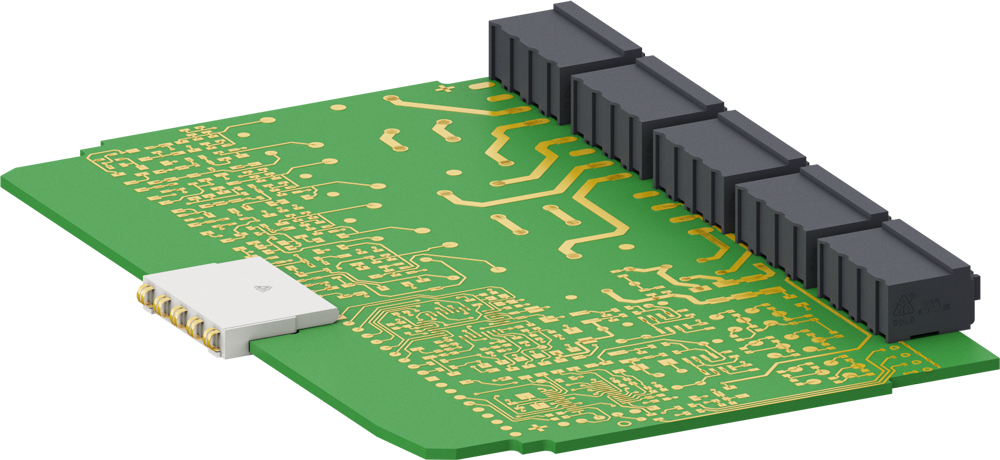

Ready for the future – the electronic enclosure KV 4600 sets new standards in modularity and function. All functionality is integrated into the front of the enclosure and thus offers a high degree of flexibility for your electronics.

During development, special attention was paid to mechanical stability. This also enables the device to be used in mobile applications. Reduce your installation effort – only a few enclosure components make up the finished device. Increase your degree of automation – the push-in terminals fulfil the high requirements of the reflow soldering process. The modular enclosure system with construction widths from 12.5 mm enables a tailor-made realisation of a large number of customer-specific applications. As an option, common communication interfaces can also be integrated.

Modular enclosure from 12.5 mm and two basic depths

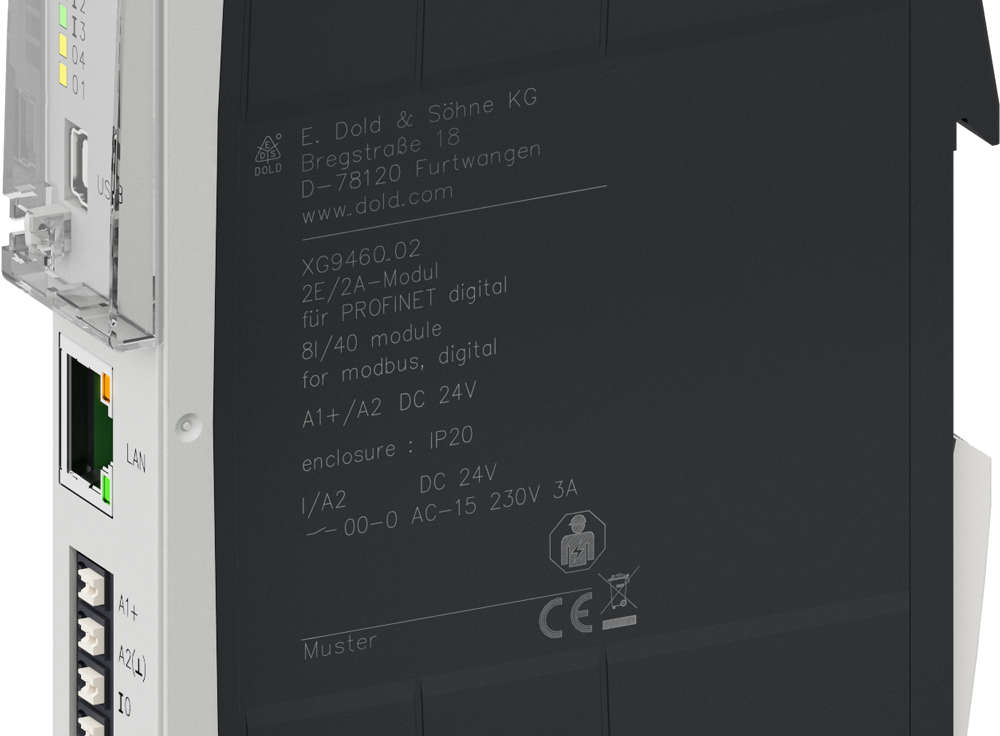

Integration of common communication interfaces

Push-in terminals in 3.5 or 5 mm pitch dimensions

Individual, multi-coloured enclosure labelling possible

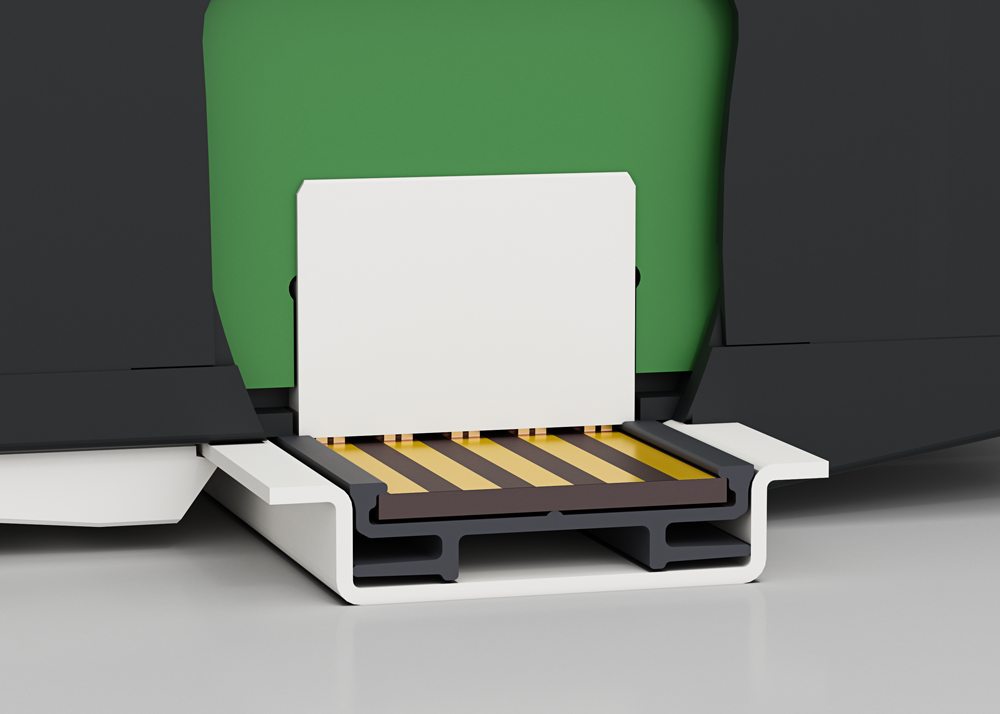

Simple integration of common bus systems in the floor area

High mechanical stability and vibration resistance

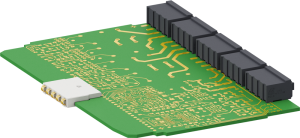

Use of up to two PCBs

Electronic enclosure KV 4600 – At a glance

Discover now all highlights and advantages.

Request personal sample

Convince yourself! Request your personal sample now to experience our electronic enclosure KV 4600 in practice.

Full functionality at the front

The large front area allows the individual arrangement of connection terminals and the integration of common communication interfaces (RJ45, D-SUB and USB connections, light conductors, wireless and NFC)

Push-in and fast diagnostics

The push-in terminals, which are suitable for automatic processing, meet the high requirements of the reflow soldering process. The integrated test point enables fast diagnostics directly on site

Cost efficiency

The PCB design allows a cost-effective design of the panel and thus reduces material costs

Intelligent design

Due to special labyrinth-like geometries, high clearance and creepage distances of up to 8 mm are achieved between the PCB and the outside contactable joining edge

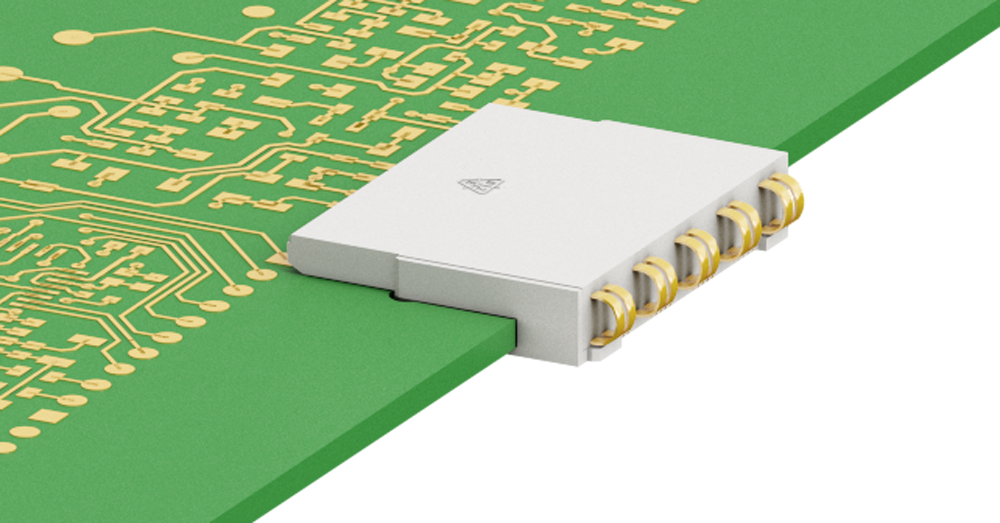

High contact reliability

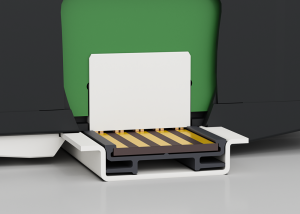

The pluggable spring contact block with gold-plated double spring contacts offers maximum contact reliability to the DIN rail bus system (In-Rail-Bus)

Simple installation and connection

The enclosure construction enables fast and simple installation snap-in – Optional variant for simple integration of common bus systems in the bottom area

Various labelling possibilities

The enclosure offers large space for individual and abrasion-resistant laser markings, pad printing or digital printing processes of your choice

Integrated ventilation slots

Lateral ventilation slots ensure optimum heat dissipation through free convection and enable applications with high thermal loads

Fast installation

Simply snap the DIN rail bus system into position – and device communication for power, signal and data transmission takes place immediately

- Full range of functions at the enclosure front

- Quick assembly due to simplified enclosure design

- PCB area of 9500 mm2 allows a wide range of applications and enables cost-effective design of the panel

- High mechanical stability and vibration resistance

- Push-in terminal technology fulfils the high requirements of the reflow soldering process

- Full functionality for display or control elements, connection technology, NFC and radio technology at the front panel

- Optional sealable, hinged front cover

- Modular widths from 12.5 mm and various construction depths available

- Use of up to two printed circuit boards per enclosure width

- High signal density due to push-in terminals with 3.5 or 5 mm pitch

- Light conductor concept – high display density with minimum space requirement

- Customer-specific adaptations can be implemented easily and cost-effectively

- Common bus concepts can be integrated into the bottom module

- Different enclosure colours available

- Optional DIN rail bus system (In-Rail-Bus)

Questions about the product?

Do you have questions about our electronics enclosures or looking for individual solutions? Please do not hesitate to contact us.

Phone: +49 7723 654 456

E-Mail: gv@dold.com

Request personal sample

Convince yourself! Request your personal sample now to experience our electronic enclosure KV 4600 in practice.

Innovative safety solutions

As a solution provider in the field of safe automation and electrical safety, DOLD offers a comprehensive portfolio from a single source. Our SAFEMASTER solutions have been used successfully worldwide for many decades.